| James,

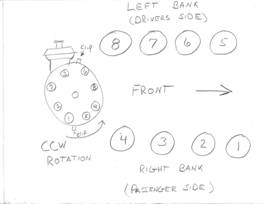

Most Ford dist. caps have a one cast into them, if not

a one there should be a round raised area. Looking

down at the cap it should be just left of the bottom clip

with the vacuum diaphragm pointing away from you.

The rotor turns counter clockwise and the fireing order is

1-5-4-8-6-3-7-2. One being the front cylinder on the

right (passenger) side of the engine.

Bring No. 1 to TDC on the comp. stroke and slip the

dist. in place with the rotor pointing towards the No. 1

position on the cap. (I like to make a mark with a Sharpie

on the dist. housing where No. 1 is with the cap off)

When you start to push the Dist. into place remember that

it will rotate as it goes down on the gear, so compensate

for that. Also if it won’t go onto the oil pump shaft,

just "bump" the engine a little while pushing

down till it goes into place.

If you have points you can put an ohm meter across them

and turn the dist. till they break contact and that will

give you a starting place for your timing, but since you

have converted to a magnetic pickup just point the rotor

to the No. 1 plug wire, aim the little pin on the

point cam to the pickup, and make minor adjustments to the

timing while cranking and it should fire. Once it fires

set the timing with a light and lock it down. Now

you are ready for break-in.

Once you have the engine started check for oil

pressure, if none in 10 sec. shut it off and find the

problem. It is best to spin the oil pump with a drill

motor and a 1/4" socket till you have oil pressure to

prim the system before you ever install the

distributor, that way you know the pump is good and the

engine holds pressure before you start it. If after all

that you don't have pressure after starting, the problem

is most likely the dist. did not connect with the pump

drive shaft.

OK, now you are running and have good oil pressure. Run

the RPM up to 2000 and hold it there for 20 min. (always

watch the oil pressure and engine temp. nothing over 210

degrees, shut it down if there is a problem) this

will mate the cam to the lifters and seat the rings. You

want the high idle so lots of oil is being thrown around

on the cam, lifters, and pistons.

I hope this will be helpful to you, feel free to ask

any more questions.

Tim |

Tech

Tips Q & A

Tech

Tips Q & A